Making our world renewable

Altri has been guiding its strategy towards creating value through its development based on the three pillars of sustainability and is therefore considered a European reference company in the production of cellulosic fibers, in sustainable forest management and in the production of renewable energy.

Replacing materials of fossil origin

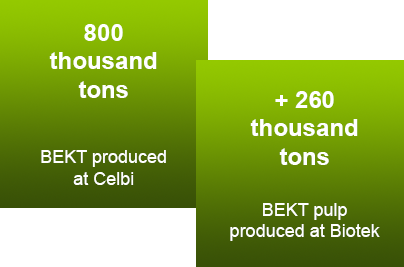

Currently, Altri has 3 mills, two of BEKP cellulosic fibers (Celbi and Biotek) and another of DWP cellulosic fibers (Caima) that essentially produces for the textile market to replace synthetic fibers of fossil origin.

We produce approximately 1.2 million tons of cellulose pulp for the market.

Promote sustainable forest management

We are responsible for the management of approximately 90.4 thousand hectares of forest in the national territory, balancing in this area production forest (essential for our activity) and conservation forest with preservation of the existing natural values. This area is certified according to international reference standards (FSC® e PEFC™).

Produce renewable energy

We are leaders in the sector of forestbased renewable energies and inject renewable electricity into the national electricity grid, avoiding approximately 174 thousand tons of CO 2 emissions (location based). About 93% of the energy sources for the manufacturing process are non-fossil.

Use renewable and sustainable materials

The opportunities for our sector are numerous, since the raw material we use - wood - is produced in a sustainable, renewable and non-fossil origin. We produce alternative products to those that use non-renewable raw materials and, in this field, Altri has been investing heavily in research and development in the search for sustainable products with high added value. 96% of the raw materials we use are renewable.

Promote efficiency in the use of resources

Our industry takes an integrated approach to the forest, uses fiber to produce cellulosic fibers, the lignin that is the glue of fibers and residual forest biomass (bark, remains of branches and leaves) for energy production in conditions that do not compromise the sustainability of the soils.

Promote circular economy and decarbonisation

We integrate the sector that is part of the solution to achieve the goal of carbon neutrality with the sequester capacity of our forest and with our renewable products that contribute to a circular economy.

The production of eucalyptus fibers is Altri's core business, which has three factories located in Portugal. The pulps produced have several applications, namely the production of paper, highlighting the production of tissue and printing and writing papers, and dissolving pulp, which is used in the production of textiles, namely through rayon.

Altri developed a strategy based on integrated forest management, with the objective of maximizing its efficient use. The forest is Altri's main asset, and the sustainable management of this resource is absolutely vital.

Altri manages, through its subsidiary Altri Florestal, around 90.4 thousand hectares of forest in Portugal, fully certified by the Forest Stewardship Council® (FSC® FSC-C004615) and by the Program for the Endorsement of Forest Certification (PEFC/13-23-002) two of the most recognized forest certification mechanisms in the world.

In addition to the cellulosic fiber production, the forest is a renewable energy source, through forest biomass or renewable cogeneration.

We aim to be a leading European company in the efficient production of eucalyptus fibers based on sustainable forest management.

In order to achieve this ambition, we aim to implement processes for the continuous improvement of environmental performance, reducing our ecological footprint, increasing the operational efficiency of our industrial units and raising productivity through the promotion of sustainable forest management.

Altri designed and implemented a conversion project at Caima mill in order to move from paper to dissolving fibers. The rational of the project was the capacity limitations of the mill and the conversion opportunity derived from the cooking solution. The conversion project was concluded in June 2015.

Currently the mill is producing around 115,000 tonnes/year of dissolving fibers.

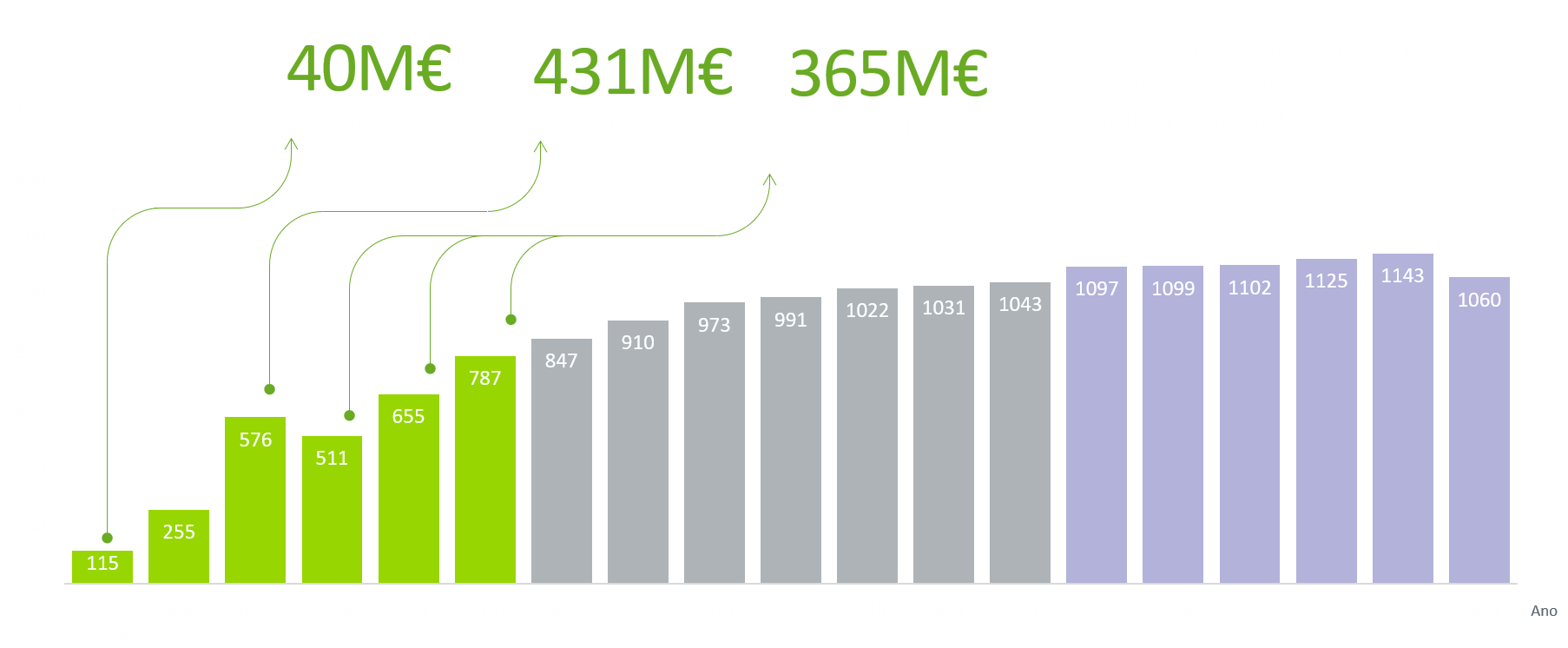

Evolution of cellulosic fibers production capacity (tonnes per year)

Increasing efficiency

Altri has systematic cost efficiency projects aiming to reduce input cost per tonne and leading to closer circuit approach, reducing systematically the amount of recycling. This is a continuous effort of the entire organization.

Value added aproach

More than adding systematically new capacity Altri's approach is based upon the idea of adding more with the same raw material.

Caima's DWP project is a clear example of the mindset as well as the presence in several international R&D teams that aim to find new economically viable uses for the wood.